The primer surfacer application is a vital step in collision repair, preparing car bodies for paint by filling imperfections, enhancing adhesion, and protecting against environmental damage. Skilled technicians use proper preparation and tailored products to ensure even coverage, minimal defects, and long-lasting durability against UV exposure, heat, and mechanical stress, maintaining both aesthetic appeal and structural integrity.

Primer surfacer application plays a pivotal role in enhancing the durability of repair work. Understanding its function within the repair process is key to achieving long-lasting results. This article delves into the critical aspects of primer surfacer, exploring how its application quality and consistency significantly impact overall durability. By examining various techniques, we provide insights on optimizing repairs for enhanced longevity.

- Understanding Primer Surfacer Role in Repair Process

- Key Factors Influencing Application Quality and Consistency

- Measuring and Optimizing Durability Through Application Techniques

Understanding Primer Surfacer Role in Repair Process

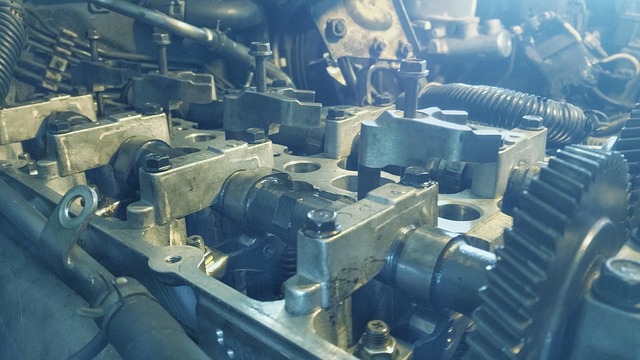

In the realm of collision repair services, the role of a primer surfacer application is pivotal to ensuring long-lasting durability for car body repair and vehicle body shop operations. This essential step in the restoration process acts as a crucial bridge between the damaged surface and the final coat of paint. By creating a smooth, even base, it prepares the car body for optimal adhesion of subsequent layers, thereby enhancing the overall quality of the repair.

A primer surfacer application is more than just a preparatory step; it’s a protective shield that fills in imperfections, evens out the surface, and provides a barrier against environmental factors that could compromise the integrity of the repair. This meticulous process forms a vital part of any reputable vehicle body shop’s arsenal, as it directly influences the longevity and aesthetics of collision repair services offered.

Key Factors Influencing Application Quality and Consistency

The quality and consistency of a primer surfacer application play a pivotal role in determining the durability of collision damage repairs or hail damage repairs on car bodywork. Several factors significantly influence this process, ensuring optimal results. First and foremost, the preparation of the damaged surface is critical. Thorough cleaning and degreasing are essential to remove any contaminants that might interfere with adhesion. Proper surface roughening techniques, such as sanding, also create a suitable profile for even primer coating.

Moreover, the choice of primer surfacer product itself matters. Different formulations cater to specific repair needs, whether it’s for steel, aluminum, or composite materials found in modern car bodywork. The viscosity and drying time of the primer should align with the application method—sprayer or brush—to achieve a smooth, uniform layer without runs or drips. Consistent thickness across the entire surface is key to ensuring even curing and long-lasting protection against corrosion, which is vital for maintaining the aesthetic and structural integrity of the vehicle.

Measuring and Optimizing Durability Through Application Techniques

Measuring and optimizing durability through application techniques is a critical step in ensuring long-lasting results for any car paint repair or collision damage restoration process. The way a primer surfacer is applied can significantly impact the final outcome of auto painting projects. Skilled technicians use various methods to ensure even coverage, minimal defects, and optimal bonding between layers. This involves careful consideration of factors like surface preparation, spraying techniques, and environmental conditions during application.

By employing advanced application techniques, professionals can enhance the adhesion and strength of the primer surfacer on damaged vehicle surfaces. Proper preparation, such as sanding and cleaning, creates a rough texture that allows for better contact between the primer and the substrate. This, in turn, leads to improved durability against factors like UV exposure, heat, and mechanical stress, ensuring that collision damage repairs stand the test of time and maintain their aesthetic appeal.

In conclusion, a thorough understanding of how primer surfacer application techniques impact repair durability is essential for achieving long-lasting results. By optimizing application quality and consistency through key factors discussed, professionals can ensure a robust and protective barrier on various surfaces. This, in turn, enhances the longevity of repairs across diverse industries. The strategic use of primer surfacer application techniques truly revolutionizes the repair process, providing not just a temporary fix but a durable solution that stands the test of time.